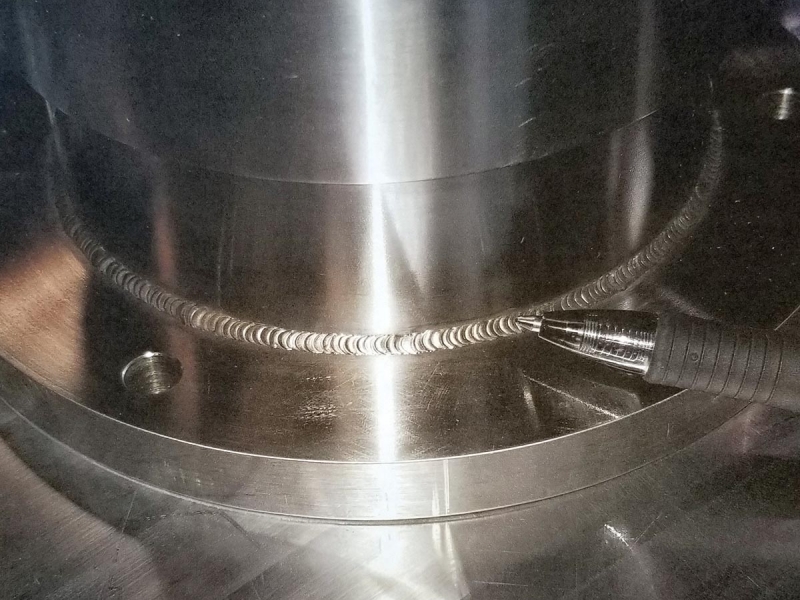

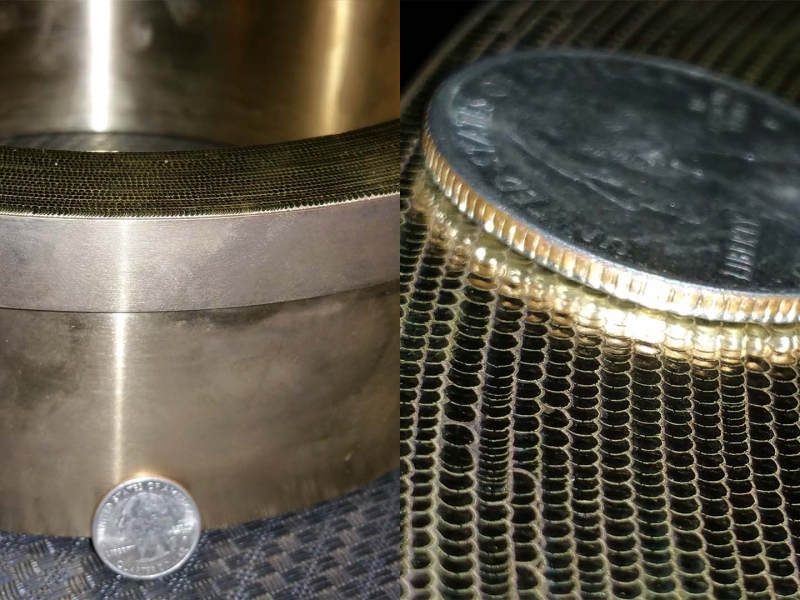

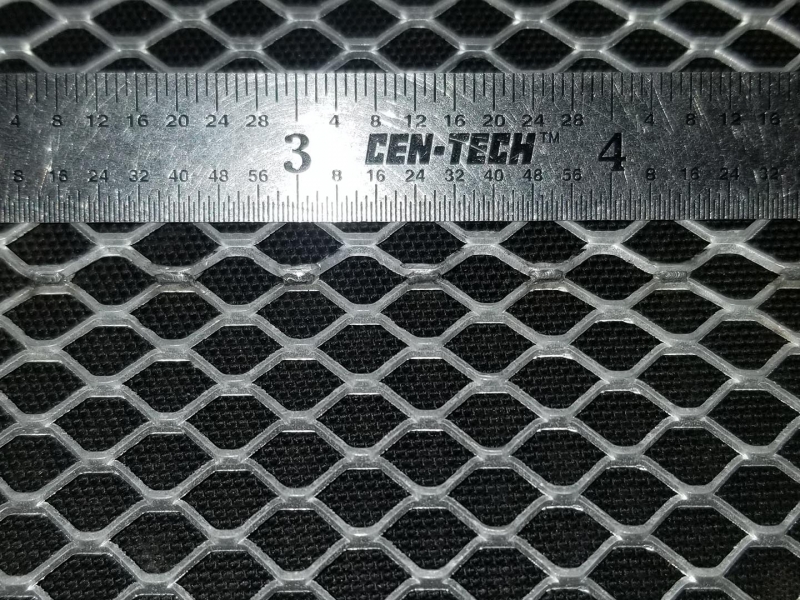

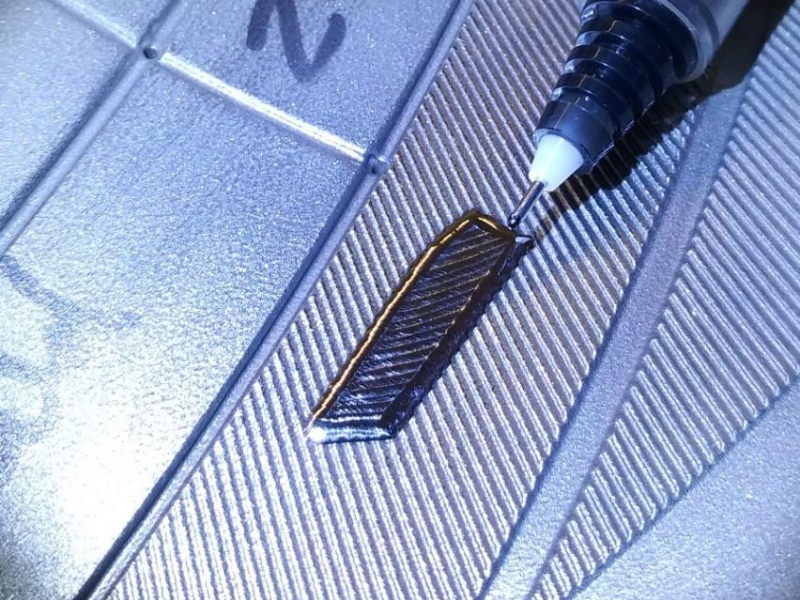

KLFW has provided detailed photos (below) in an attempt to highlight our comprehensive microscopic laser welding skills. These photos are examples of some common, uncommon, and various engineering changes we have encountered and welded to client satisfaction. (All photos used by client permission only.)

Welds shown here are routinely and successfully welded by the staff at KFLW and are composed of alloys, and likewise welded using the same, or compatible alloys such as:

- All common tool steels such as A-2, D-2, H-13, S-7, P20, 420, 420F (Royalloy), and many others.

- Nonferrous alloys such as beryllium copper, Amco alloys, pure copper, aluminum series (2000’s, 3000’s, 4000’s, 5000’s, 7000’s), stainless steel series (300’s, 400’s) in addition to aluminum zinc or aluminum magnesium alloys

- Preheating high carbon alloys can be avoided due to the inherent advantages of YAG microscopic laser welding.

- Exotic alloy workpieces composed of 6Al-4V titanium, pure titanium, inconol, waspalloys, L605, Hastalloy, 250 and 350 series marraging (martensetic aging) steels, anviloy, and others.